Custom Round Hay Baler by Italy Ever Power

Italy-made round hay baler from Ever Power. Tailored for your forage type. Get a quote today—direct from the manufacturer & global supplier.

🌾 Round Hay Baler That Actually Works With Your Crop—Not Just the Brochure

Here at Ever Power, we’re not just another manufacturer—we’ve been building and field-tuning round hay balers in our Reggio Emilia factory for over 18 years. And as a direct supplier, we know one size never fits all. What really matters? How well your baler handles your specific crop, in your soil, under your weather. That’s why ours is engineered from the ground up for real-world biomass—not lab-perfect hay. Whether it’s dewy alfalfa in Lombardy or dusty wheat straw in Kazakhstan, this machine adapts. No gimmicks. Just reliable baling, season after season.

⚙️ 1. Product Overview

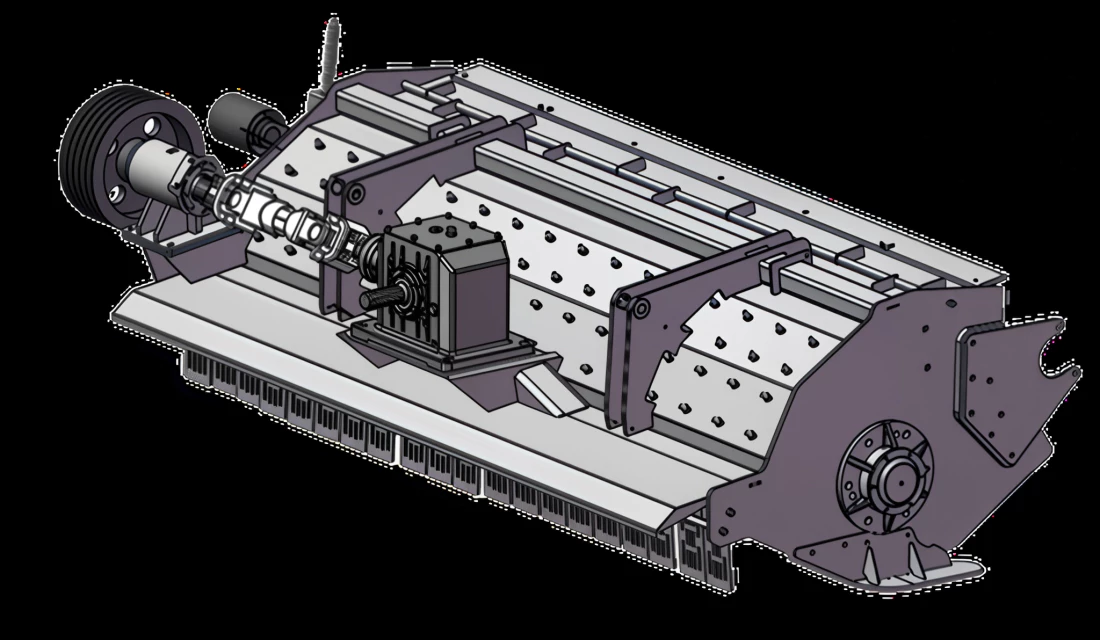

This product is a newly developed product specifically designed for agricultural and livestock baling operations using small-horsepower tractors. The bale weight is between 200-400 catties, facilitating transportation. It is mainly used for baling straw and forage from various crops such as corn, rice, wheat, and soybeans after harvest, forming round bales. This series of products adopts an "axial flow" semi-forced feeding mechanism and a camless, ringless picking mechanism. Compared with traditional methods, this mechanism reduces power consumption, increases feeding capacity, and reduces the chance of straw clogging, thus increasing operating efficiency by nearly double. This mechanism was independently developed and designed by our company and possesses exclusive intellectual property rights.

Product Highlights:

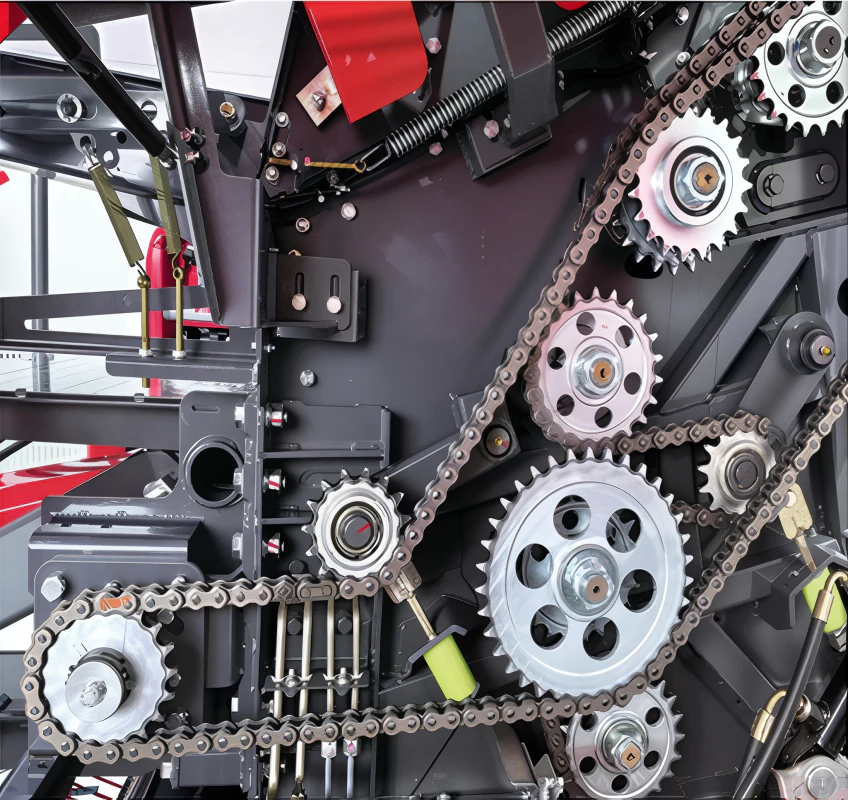

The front and rear chambers utilize double-sided 16A heavy-duty chains, increasing compression pressure and resulting in higher bale density, reaching 200-400 catties, meeting customer needs.

The entire machine uses heavy-duty chains and maintenance-free bearings, resulting in lower failure rates and simpler maintenance. The machine is constructed with wear-resistant manganese steel plates from Angang Steel, offering high strength and long service life, capable of handling standard materials and preventing chamber rupture. The manganese material discharge plate is highly smooth, wear-resistant, and resistant to high and low temperatures, with good insulation properties and anti-aging capabilities, outperforming iron discharge plates.

This machine can be connected to both a spring-type pickup and a hammer-claw pickup specifically designed for collecting cotton stalks, enabling the collection and baling of Croatian cotton stalks, eliminating the need for raking and bundling, thus reducing the cost of cotton stalk collection.

📏 2. Technical Specifications

| Item | Unit | Specification |

| Model Name | / | 9YG-1.0C Type Round Baler |

| Drive Method | / | Belt Drive |

| Baler Width | mm | 2400 |

| Baler Structure | / | Claw Type |

| Inlet Structure | / | Knife + Blade + Screen |

| Press Structure | / | Welded Steel |

| Press Room Width | mm | 1250 |

| Press Room Diameter | mm | Φ1000 |

| Number of Press Work Units | / | 16 (sections) |

| Roller Diameter | mm | Φ222 |

| Crushing Method | / | Automatic Welding |

| Power Supply | Kw/hp | ≥69.8/95 |

| Structure Weight | kg | 3198 |

| Power Output Shaft Speed | r/min | 540 |

| Work Condition | / | Outdoor Type (L×W×H) |

| Grass Size (Length × Width × Height) | mm | 3800 × 2850 × 2200 |

| Grass Density Control | / | Frequency Converter Control |

| Grass Size (Width × Height) | mm | Φ100 × 1250 |

| Grass Density | kg/m³ | 115-200 |

| Yield Rate | / | 40-80 |

| Roller Distance | mm | 2100 |

| Operating Speed | km/h | 5-20 |

| Screen Size (Length × Width) | / | 2000 × 1.25 m / flat |

| Number of Claws | / | 20 |

✅ 3. Six Real-World Advantages—Forged in Fields, Not Focus Groups

- Adaptive Pickup with Ground-Following Float

Most pickups jam when switching from light grass to heavy corn stover. Ours uses a parallelogram linkage that maintains consistent ground contact—even on rolling terrain. We’ve tested it on fields with 15cm undulations. No skips. - Crop-Specific Chamber Tuning (Yes, Really)

Adjust roller pressure and rotor speed via two simple hydraulic valves. Alfalfa? Keep it light. Wheat straw? Crank it up. You don’t need a tablet—just feel and fine-tune from the cab. - Moisture-Tolerant Performance

Morning dew? Light rain delay? No problem. The chamber’s anti-wrap coating and open-throat design prevent clumping. We’ve run it at 18% moisture in Emilia-Romagna springs—zero clogs. - Net Wrap That Stays Put—Even in Humidity

Our cut-and-hold mechanism secures the net tail so it doesn’t unravel during ejection. Critical if you’re stacking bales in Morocco or Ukraine where humidity spikes overnight. - Tool-Free Access to High-Wear Zones

Belts, bearings, tines—reachable in under 10 minutes. One farmer in Alberta changed a pickup bearing during lunch break. That’s uptime you can bank on. - Global Parts, Local Support Mindset

As both manufacturer and supplier, we stock common wear parts in Italy, Poland, and Casablanca. Most orders ship in 48 hours. No waiting weeks for a $20 seal.

🔍 4. How to Pick the Right Round Hay Baler—Without Overpaying or Under-Buying

It’s not about horsepower alone. Ask yourself: What am I baling, and what happens to the bale afterward?

- Dairy farmers in Germany or Wisconsin baling alfalfa? Prioritize leaf retention and net wrap reliability. A slightly slower, gentler machine pays off in feed quality.

- Grain growers in Kazakhstan or Saskatchewan clearing wheat straw? You need torque, wide pickup, and abrasion-resistant parts. Soil contamination wears out cheap rollers fast.

- Contractors in Argentina or Romania serving multiple clients? Go for modular design—quick-change wrapping systems and easy calibration save hours between jobs.

- Bioenergy projects in Spain or Turkey using sorghum or miscanthus? Ensure the chamber throat is wide enough (>1.8m) and the pickup can handle tangled, fibrous stems.

🌍 5. Where It’s Used—And What It’s Baling

This isn’t a “hay-only” toy. In our experience, the best balers earn their keep across seasons:

- Alfalfa & Clover → Dairy feed in France, export pellets from Argentina

- Wheat/Barley Straw → Mushroom substrate in Poland, bedding in Egypt

- Corn Stover → Erosion control in Iowa, biogas feedstock in Germany

- Rye/Vetch Cover Crops → Organic residue management in Italy and Canada

- Sorghum Sudan Grass → Summer forage in Texas and Australia

🗣️ 6. What Real Users Say—No Fluff, Just Field Truths

Lars J., Mixed Farm – Skåne, Sweden

“Bale timothy and clover mix for horse owners. Used to lose leaves with our old baler—customers complained. Switched to Ever Power last year. Now they say the bales ‘look fresher.’ Even works in our short summer window. Solid build.”

⭐⭐⭐⭐½Nikolai V., Grain Co-op – Altai Krai, Russia

“We cleared 1,200 ha of barley stubble. Dusty, dry, full of small stones. This baler’s pickup hasn’t bent once in two seasons. Net wrap holds through Siberian winds. Parts from the EU arrived in 6 days—faster than local dealers.”

⭐⭐⭐⭐☆Carla M., Forage Exporter – Córdoba, Argentina

“Ship alfalfa to Saudi Arabia. Every % of leaf loss = lost revenue. This machine keeps fines intact. Also, bales are uniform—container loading is 20% faster. Yes, it cost more upfront… but ROI was clear by Year 2.”

⭐⭐⭐⭐⭐

Related Products

- Net Wrap Rolls

- Baler Belts (Rubber & Polyurethane)

- Pickup Tines & Reels

- Twine Knotters & Twine Discs

- Hydraulic Cylinders

- Roller Bearings & Bushings

- Drive Chains & Sprockets

- PTO Shafts & Guards

- Bale Chamber Scrapers

- Needle Guards & Safety Sensors

🔮 7. Industry Trends: Where Round Baling Is Headed

Demand isn’t slowing—it’s evolving. Buyers now want predictable bale specs, not just volume. Export markets (UAE, Turkey, South Korea) reject inconsistent loads. That’s pushing balers toward smarter density control and traceability.

Also, sustainability is reshaping residue use. Corn stover isn’t “waste” anymore—it’s carbon credit material or biogas input. Machines must handle coarse, irregular biomass without constant adjustment.

And labor shortage? Huge. Simpler operation, fewer breakdowns, remote diagnostics—these aren’t luxuries. They’re survival traits. That’s why we’re investing in modular design and multilingual digital support, not flashy screens.

❓ 8. FAQ – Real Questions, Real Conversations

(Speakable + FAQPage Schema Ready)

Q: What’s the actual cost of a round hay baler for alfalfa farming in Germany?

A: Prices vary by configuration, but expect €38,000–€52,000 for a fully equipped model. We offer direct quotes—no dealer markup.

Q: Where can I find a reliable round hay baler supplier in Kazakhstan for wheat straw?

A: We ship directly to Almaty and Nur-Sultan. Most clients get delivery in 10–14 days with full customs support.

Q: How much does it cost to replace net wrap system parts on Italian-made balers?

A: Standard net cutter kit: €85. Full assembly: €220. All parts in stock—shipped same day.

Q: Which round hay baler works best for corn stover in Iowa custom harvesting?

A: Our HD-180 model—with reinforced pickup and open-throat chamber. Designed specifically for Midwest residue.

Q: When should I choose net wrap over twine for hay baling in humid Morocco?

A: Always use net wrap if bales sit outside >48 hours. Twine won’t prevent water ingress in coastal humidity.

Q: Can I get a quote for a CE-certified round hay baler shipped to Argentina?

A: Absolutely. We’ve supplied 37 units to Córdoba and Santa Fe since 2022. Request your quote today.

Additional information

| edited | by hyw |

|---|---|

| model | 1.0C |