Why Conditioning Isn't Optional: The Science Behind the Swath

Let's talk about what happens inside a standing plant. In a grass or legume stem, most of the water is locked in the waxy, tubular stem. Simply cutting it and leaving it to dry is like trying to empty a bottle with a sealed lid—it takes forever. A mower-conditioner, like our TurboDry, applies controlled mechanical action immediately after the cut. We use a heavy-duty intermeshing rubber roll system (though flail options are available for certain crops) that gently squeezes and bruises every stem, creating thousands of microscopic cracks in that waxy layer without pulverizing the valuable leaves. This allows internal moisture to escape at 2-3 times the rate of an uncut stem.

But here's the trick most operators don't realize: conditioning is only half the battle. The other half is swath management. How the machine lays that conditioned crop down is just as critical. An old sickle bar mower leaves a dense, tangled mat that dries from the top down, often leaving the bottom layer to mold. The TurboDry’s patented swath hood and deflector system creates a wide, uniform, and fluffy “window” of crop. This allows air and sunlight to penetrate from all sides, and it lets the swath dry more evenly. In our experience, this one-two punch of effective conditioning and intelligent swath formation can reduce field curing time by 30-50% compared to just mowing. That’s the difference between baling at 18% moisture and watching a thunderstorm roll over hay that’s still at 40%.

Technical Specifications: Built for Performance & Reliability

The TurboDry series is designed to match various scales and crop types. Below are the key specs that define its capability.

| Item | Unit | Specification |

| Model Name | / | 9GQY-3.2 Type Grass Crushing Machine |

| Suspension Mode | / | Side suspension type |

| Cutting Width | m | 3.2 |

| Cutter Structure Type | / | Rotating type |

| Number of Blades | pcs | 8 |

| Pressure Device Type | / | Rotary blade press |

| Release Height | m | 0.8-2.2 |

| Power Supply Range | KW/hp | ≥80.88/110 |

| Working Speed Range | km/h | 6~15 |

| Power Output Speed | r/min | 540 |

| Number of Blades | pcs | 16 |

| External Dimensions | mm | 6750×3500×2000 |

| Average Cutting Height | mm | ≥50 |

| Operators Required | persons | 1 |

| Machine Weight | kg | 2185 |

Product Highlights

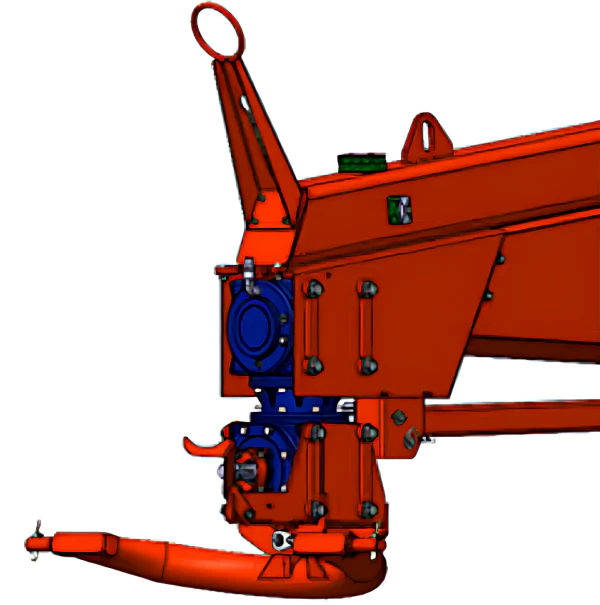

The towed mower-conditioner is designed for harvesting grasses and reeds. Its super-floating protection device automatically lifts the cutting head when encountering rocks or tree roots, then returns to the working position after clearing the obstacle, protecting the cutter head and improving efficiency. Featuring a suspended double-suspension system, the cutter head and conditioning unit are independently mounted, allowing for excellent contour following capabilities and suitability for various terrain conditions.

The offset traction protection device is more suitable for observing working conditions; it adopts an integrated oil-bath gearbox, offering high reliability and low maintenance costs. The newly designed cutter head protection device features a circular cutter head with excellent passability, effectively preventing damage from stones, and the offset traction cutting action is clean and efficient.

The impact-type crimper is suitable for high-yield grasses and reeds. The roller-type crimper is suitable for water chestnut plants.

The hay mower conditioner provides clean cuts, even stubble, and a level cutting surface, laying a good foundation for future growth.

Twisting performance: Achieves the cleanest cut in all conditions, with double-sided extension capabilities.

Circular blade disc: Significantly improved performance;

High oil content in the side walls: Provides excellent cooling and lubrication.

Low noise: Special gear structure;

Excellent cutting performance: Clean cuts, even stubble, and a level cutting surface;

Fully welded gearbox: No risk of oil leakage, large capacity.

The impact-type flattening machine is highly efficient, using impactors to break through the waxy layer of the nail, allowing moisture to evaporate and completing the drying process. The impact-type flattening machine employs a semi-oscillating design. During operation, the impactors rebound, creating more space for stones and foreign objects to pass through, thus effectively protecting the impactors.

The TurboDry Advantage: Six Ways It Transforms Your Harvest

1. Dramatically Faster Field Curing

Intensive stem conditioning combined with a perfect, fluffy swath reduces drying time by up to 50%, getting your hay to safe baling moisture hours or even a full day sooner.

2. Superior Nutrient Preservation

Faster drying means less respiration loss of sugars and starches, and gentle rubber rolls minimize leaf loss, preserving the protein and energy value of your forage.

3. Unmatched Reliability in Heavy Crops

Built with a heavy-duty gearbox, reinforced driveline, and high-clearance design to power through thick, lodged, or wet grass without clogging or breaking down.

4. Perfect Swath for Any Condition

Adjustable swath hoods and deflectors let you lay the crop wide for sun or narrow for dew, optimizing the dry-down process based on weather and crop type.

5. Exceptional Leaf Retention

The intermeshing rubber roll system is far gentler on delicate legumes like alfalfa and clover than aggressive flail conditioners, keeping the valuable leaves on the stem.

6. Reduced Weather & Rain Risk

Shaving a day off drying time significantly lowers the chance of having valuable hay rained on, which is the single biggest cause of quality deterioration and loss.

Selecting Your Mower-Conditioner: Key Questions to Ask

Choosing the right model isn't just about width; it's about matching the machine's strengths to your specific challenges. First, define your primary crop. For alfalfa and other tender legumes, you need gentle conditioning—intermeshing rubber rolls are the gold standard. For pure grass hay or silage, a flail conditioner can be very effective and is often more forgiving of rocks. Second, assess your typical acreage and weather patterns. If you frequently battle narrow weather windows, maximizing dry-down speed (with both rolls and swath management) is your top priority. Third, be realistic about your tractor's horsepower and hydraulic capacity. These are power-hungry implements, especially in heavy crops. Under-powering leads to inefficiency and wear. Finally, consider your terrain. A robust, well-balanced machine with good ground following will produce a more consistent swath on rolling land. The right choice is the one that makes your hay faster and better, not just cuts it wider.

Beyond Hay: Versatility Across Forage Systems

The TurboDry's value extends across the entire forage production spectrum. It is, of course, the cornerstone of high-quality dry hay production for dairy, beef, and equine markets where every hour of drying time and every leaf saved matters. For haylage (baleage) makers, proper conditioning is non-negotiable; it's the critical first step to achieving the ideal 45-55% moisture content for perfect fermentation in the bale wrap. In large-scale silage operations (chopping), conditioning accelerates wilting, allowing you to chop sooner at the target moisture for optimal packing and fermentation in the bunk. It's also invaluable for pasture renovation, cleanly cutting and conditioning old growth. This machine isn't a luxury for one type of farm; it's the efficiency engine for any serious forage producer looking to take control of their harvest timeline and output quality.

What Farmers Say About the TurboDry Difference

"Our dairy in Wisconsin runs three TurboDry 280s. In our humid climate, getting alfalfa to dry is everything. With these machines, we're consistently baling a day sooner than our neighbors using older disc mowers. The leaf retention is noticeable, and our nutritionist sees the difference in the feed analysis."

— Mark S., Dairy Farm Manager, USA

"Farming in Ireland's unpredictable weather, speed is safety. Since switching to a TurboDry, our grass for silage wilts so much faster. We can often chop within 24 hours, which means we catch the best weather and get a much better fermentation in the pit. The machine is built like a tank, too."

— Sean O., Beef & Silage Farmer, Ireland

"As a contractor in New Zealand, I need gear that's reliable and does a top job for my clients. The TurboDry lays down a perfect, even swath that's easy for the rakes to pick up. It handles our tall ryegrass without issue, and the service backup from the supplier has been excellent."

— Chloe W., Agricultural Contractor, New Zealand

The Future of Forage Harvesting: Integration & Intelligence

The next generation of mower-conditioners is moving beyond brute mechanical force towards integrated intelligence and precision. We see a clear trend towards on-the-go conditioning adjustment. Imagine sensors that measure crop moisture and density, automatically adjusting roll pressure or flail speed from the tractor cab to optimize conditioning for every square meter of the field. Furthermore, telematics and data integration will become standard, providing real-time data on machine performance, location, and maintenance needs, feeding directly into farm management software. There's also a push for greater fuel and operational efficiency through improved hydraulic systems and lighter, stronger materials. The goal is to give the operator more control with less guesswork, maximizing forage quality while minimizing inputs and downtime. The TurboDry platform is being developed with these smart, connected futures in mind.

Frequently Asked Questions About Mower-Conditioners

What's the price of a new 9ft mower-conditioner in the US market?

As a manufacturer, we offer competitive pricing for the value delivered. A TurboDry model in that size range represents a significant investment that pays back through faster harvests and higher quality forage. For a precise quote based on your specs and location, please contact our sales team.

Which is better for my UK farm: rubber rolls or a flail conditioner?

For UK grasses and mixed swards focused on quality, rubber rolls are generally preferred. They are gentler, cause less leaf loss, and are more energy-efficient. Flails are tougher for very heavy, woody crops or where stones are a major concern, but can be harsher on the forage.

How much HP do I need to run a 3m mower-conditioner?

As a rule of thumb, you need a minimum of 15-20 PTO horsepower per foot of cutting width. So for a ~10ft (3m) machine, a reliable 150-200 HP tractor is recommended, especially for hilly ground or heavy crops. Always check the specific model's requirements.

When should I replace the conditioner rollers?

Replace rubber rolls when the tread pattern is significantly worn smooth or if they develop cracks and chunks missing, as this reduces conditioning efficiency. With normal use, this might be every 4-6 seasons. Inspect them at the start of each harvest.