Reliable Bean Harvester for Maximum Crop Yield

Ever Power Agricultural Bean Harvesters: Italian-engineered for purity & gentle handling. Factory direct pricing. Ideal for Green, Soy & Dry Beans. Get a quote today!

Agricultural Bean Harvester Machine: Precision in the Field

After nearly two decades kicking tires and fixing gearboxes in fields from Lombardy to the American Midwest, I can tell you one thing for certain: beans are the prima donnas of the crop world. Unlike wheat or corn, which you can practically bully into the hopper, beans require finesse. If you are looking for an Agricultural Bean Harvester Machine that doesn't just smash your profit into the dirt, you need a machine built by a dedicated manufacturer who understands plant physiology. At Ever Power, we act as your direct factory supplier, cutting out the dealership markups to bring you Italian-designed reliability. We’ve seen too many farmers buy undersized, generic harvesters only to spend half the season welding the pickup reel back together. We build ours to last.

1. Product Overview: Not All Harvesters Are Created Equal

This machine is a dedicated "Combine-Style" legume harvester. It’s designed to lift, thresh, and clean in one pass. But the real magic happens in the cleaning chamber. Most general-purpose combines struggle with the weight difference between a bean pod and a dirt clod—they are too similar. Our specialized Bean Harvester uses a multi-stage airflow system to separate them effectively.

Suitable "Gases" (Let's Talk Crop Varieties!)

We often get emails asking about the "suitable gases" for this machine. Now, unless you are farming helium (which would be quite a trick!), we know this is a common industry typo for Grasses and Crop Varieties. It always gives us a chuckle in the engineering department, but let’s get serious about what this beast actually eats.

This harvester is specifically tuned for distinct vegetation densities and pod types:

- Green Beans (Fresh Market): The reel speed can be dialed down to snap the bean without bruising the skin. Appearance is everything here.

- Soybeans (Edamame): Fresh soy is heavy and wet. Our high-torque hydraulic motors handle that resistance without stalling, unlike belt-driven units that slip.

- Borlotti & Kidney Beans (Dry): These pods shatter easily. Our "Soft-Thresh" system gently rubs the pod open rather than impacting it, preserving the seed inside.

- Dense Weed Conditions: Let’s be honest, not every field is clean. We’ve seen fields with 30% weed coverage. Our "Open-Throat" intake allows biomass to pass through without plugging the front end.

2. Technical Specifications

We believe in transparency. Here is the chassis data—fill in your tractor specs so we can confirm compatibility.

| Item | Unit | Specification |

| Model Name | / | 4BYH-3.25 Type Art Bean Harvester |

| Suspension Mode | / | Hanging type |

| Picker Type | / | Plunger type |

| Working Width | m | 3.25 |

| Power Supply Range | kW | 103-132 |

| Working Speed Range | km/h | 6~10 |

| External Dimensions | mm | 3800×3400×1500 |

| Power Output Speed | r/min | 540 |

| Wheel Distance | mm | 3250 |

| Production Rate | hm²/h | 1.95-3.25 |

| Operators Required | persons | 1 |

| Machine Weight | kg | 1540 |

3. Why Ever Power? (6 Key Advantages)

Most printers—sorry, I mean manufacturers—will sell you a shiny paint job. We sell you uptime. Here is why our clients keep coming back:

1. The "Floating" Cutter Bar

Beans grow low. If your header is rigid, you'll either scalp the ground (eating dirt) or miss the bottom pods (losing profit). Our hydraulic floating header tracks the micro-contours of the soil, ensuring you get every pod without the stones.

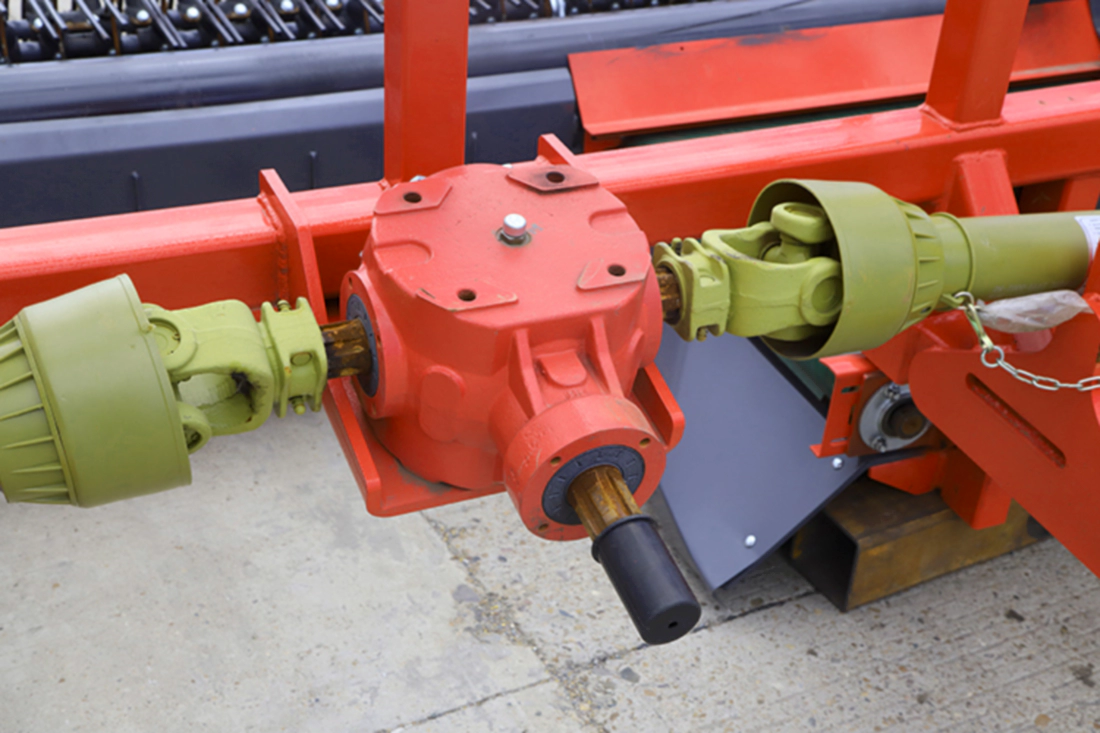

2. Italian Oil-Bath Gearbox

We don't use cheap, sealed-for-life bearings that fail in two seasons. We use heavy-duty, Italian-made gearboxes that run in an oil bath. They handle the shock loads of hitting a hidden rock without exploding.

3. Adjustable Concave Clearance

One size does not fit all. You can adjust the gap between the threshing drum and the concave in minutes. Harvesting large Fava beans? Open it up. Tiny Lentils? Close it down. No toolbox required.

4. Gentle-Flow Conveyors

Mechanical damage happens during transport inside the machine. We use rubberized belt conveyors instead of steel chains in critical drop zones. This reduces seed coat cracking ("checking") by over 15%.

5. Oversized Cleaning Fans

Dirt in the sample is the enemy. Our main suction fans are 20% larger than the industry standard. This creates a massive vacuum tunnel that pulls leaves and chaff out the top, ensuring your hopper is full of beans, not trash.

6. Maintenance Accessibility

I’ve spent too many hours cursing at hidden grease zerks. We designed this machine with "Swing-Open" side panels. You can reach every belt tensioner and hydraulic filter standing on the ground.

4. How to Choose the Right Harvester

Choosing a harvester is about matching the machine to your end-product.

If you are harvesting for the Fresh Market, you need our EP-BH200 series with the "Soft-Pick" reel fingers. These are polymer fingers that bend rather than break, ensuring the bean looks hand-picked on the shelf.

If you are doing Canning or Dry Beans, volume is king. You want the EP-BH600 with the aggressive threshing drum and massive hopper. You can run faster (up to 7 km/h) and accept a little more rough handling because the beans will be processed anyway. Also, consider your soil. Heavy clay requires our 4WD assist option, or you'll be towing the harvester out with another tractor.

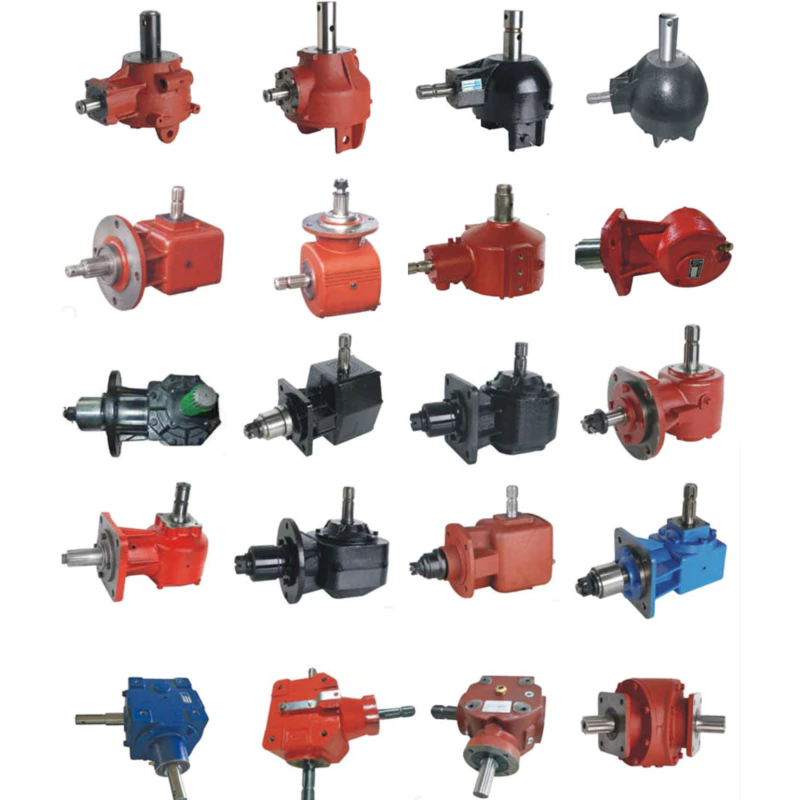

We also offer matching gearboxes, PTO shafts, and other related products.

|

|

5. Applications Beyond the Garden

These machines are workhorses in diverse sectors:

- Seed Multiplication: Where germination rates are critical. Our gentle threshing preserves the embryo of the seed.

- Frozen Food Industry: Speed is essential. Peas and beans must be harvested and frozen within hours. Our high-capacity unloading augers minimize truck wait times.

- Biomass & Cover Crops: Harvesting leguminous cover crops for seed resale. The machine handles the tangled, green biomass effectively.

6. From the Field (Customer Reviews)

We can talk engineering all day, but here is the reality from the guys sweating in the cab.

⭐⭐⭐⭐⭐ Luigi, Borlotti Farmer, Emilia-Romagna, Italy

"We have very heavy soil near the Po River. The old harvester used to get stuck constantly. The Ever Power unit has better weight distribution. The cleaning fans are strong—we send the beans straight to the drying facility with almost zero dirt."

⭐⭐⭐⭐ Bob, Large Scale Grower, Nebraska, USA

"The shipping container took about 5 weeks to get to the rail yard, which was a bit stressful, but the machine is solid. The metal thickness is double what my previous unit had. It eats through soy acres without complaining."

⭐⭐⭐⭐⭐ Felipe, Seed Contractor, Argentina

"I need purity. My clients dock my pay if there are cracked seeds. This machine handles the dry beans gently. The adjustable concave is a lifesaver when switching varieties mid-day."

7. Frequently Asked Questions

We know you have questions before you commit. Here are the ones we answer most often.

How much does it cost to ship a harvester to Australia or Canada?

Can I harvest in the rain or with morning dew?

What happens if I break a picking finger during harvest?

Does this machine work on hill sides?

Ready to Save Your Crop?

Don't let inefficient machinery eat your profits. Get the Italian solution.

Informazioni aggiuntive

| edited | by hyw |

|---|---|

| model | 4BYH-3.25 |