Agricultural machinery Bean Harvester In Italy

Ever Power Italy: Factory-direct Bean Harvesters. Heavy-duty agricultural machinery designed for low loss & high purity. Ideal for Borlotti & Green beans. Get a custom quote!

After standing in dusty fields from Puglia to the Po Valley for nearly two decades, we’ve learned one undeniable truth: beans are unforgiving. Unlike corn or wheat, a bean pod is a fragile thing. When you are looking for a reliable Bean Harvester, you aren't just looking for a machine that cuts plants; you need a surgeon. As a dedicated manufacturer and global supplier based in the heart of Italy’s agricultural machinery district, Ever Power has refined the art of the harvest. We offer factory-direct solutions that cut out the middleman markup. Most printers—sorry, I mean importers—don't realize that the secret isn't in the horsepower; it's in the pickup reel speed and the threshing geometry. We build machines that respect the crop.

1. Product Overview: The Gentle Giant

This Agricultural Machinery Bean Harvester is what we call a "Combine-Style" specialist. It is designed specifically for legumes that grow close to the ground. Whether you are harvesting dry beans for canning or fresh green beans for the market, the challenge is always the same: how do you get the pod off the vine without cracking it open or filling the hopper with dirt?

Our machine utilizes a multi-stage cleaning system that we’ve perfected over years of field testing in Emilia-Romagna. It gently lifts the plant, strips the pods, and then uses air density separation to remove leaves and soil.

Suitable "Gases" (Let's Talk Varieties!)

We often get inquiries asking about the "suitable gases" for our machines. Now, unless you are farming helium (which would be a neat trick), we know you mean Bean Varieties and Crop Types. It's a funny translation error we see in the industry all the time! But let’s get serious about what this machine actually eats:

- Borlotti & Kidney Beans: These have heavy pods. Our harvester uses a specialized drum setting to handle the weight without shattering the dry casing prematurely.

- Green Beans (Fagiolini): For the fresh market, appearance is everything. The harvester's "soft-touch" rubber fingers ensure the beans don't get bruised.

- Soybeans (Edamame style): Handling fresh soy requires a delicate touch to avoid crushing the bean inside the pod.

- Cannellini & Navy Beans: Small, white, and prone to splitting. We have a fine-mesh concave screen specifically for these smaller varieties.

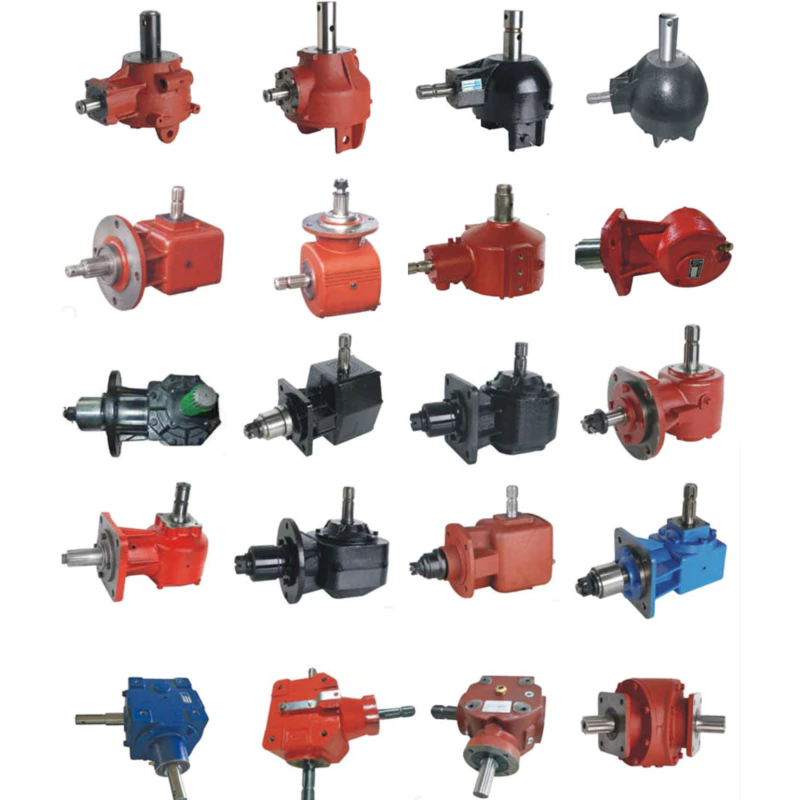

We also offer matching agricultural gearboxes and PTO shafts.

|

|

2. Technical Specifications

We believe in transparency. Here are the specs for our core models. (Please fill in your specific requirements for custom orders, as we build to suit).

| Item | Unit | Specification |

| Model Name | / | 4BYQ-2.6 Type Art Bean Harvester |

| Suspension Mode | / | Hanging type |

| Picker Type | / | Plunger type |

| Working Width | m | 2.6 |

| Power Supply Range | kW | 66-88 |

| Working Speed Range | km/h | 6~10 |

| External Dimensions | mm | 2333×2870×1182 |

| Power Output Speed | r/min | 540 |

| Wheel Distance | mm | 2600 |

| Production Rate | hm²/h | 1.56-2.6 |

| Operators Required | persons | 1 |

| Machine Weight | kg | 1100 |

Product Details

|

|

3. Why Ever Power? (6 Key Advantages)

In our experience, a harvester looks good in the brochure, but the truth comes out when it hits a rock in the field. Here is why our machines stay running:

1. The Floating Cutter Bar

Beans grow low. If your cutter bar is rigid, you either miss the bottom pods or you dig into the dirt. Our cutter bar "floats" on hydraulic sensors, following the micro-contours of the ground to get every single pod without eating soil.

2. Italian Gearbox Technology

We don't use generic components. The heart of the machine is a heavy-duty, oil-bath gearbox manufactured right here in Italy. It handles the high-torque start-ups of a full drum without snapping shear bolts.

3. Adjustable Threshing Clearance

The trick is adaptability. You can adjust the concave clearance in minutes. Switching from large Kidney beans to tiny Lentils? Just turn the crank. No need to swap out the entire drum.

4. Gentle-Flow Conveyors

Mechanical damage happens during transport. We use rubberized belt conveyors instead of metal chains in critical areas. This reduces "skinning" (damaging the bean skin) by over 15% compared to older models.

5. High-Velocity Cleaning Fans

Dirt in the hopper equals dockage fees at the cannery. Our dual-fan system creates a wind tunnel that blows chaff and dust out the back, leaving only clean pods in the tank.

6. Factory Direct Support

When you buy from us, you get the engineers who built it. If you have a technical question during harvest, you aren't calling a call center; you're calling the factory floor.

4. How to Choose the Right Bean Harvester

Choosing the right machine depends on your end-goal. Are you selling to a cannery or a fresh market?

If you are doing Fresh Market Green Beans, you need a harvester with a "box-filling" system rather than a bulk hopper, to prevent the beans from crushing each other under their own weight. For Dry Beans, capacity is king. You want the biggest hopper possible to minimize unloading downtime. Also, consider your soil. If you have heavy clay (like we see in parts of Tuscany), you need a 4WD option with wider tires to prevent compaction and bogging down.

5. Applications in the Field

These machines are working hard globally, not just in Italy.

- Commercial Cannery Operations: Harvesting tons of Borlotti beans for soup mixes. The high cleaning efficiency reduces the factory's washing costs.

- Seed Production: Where purity is non-negotiable. Our harvesters are used by seed companies because the gentle handling ensures high germination rates (cracked seeds don't grow!).

- Frozen Food Supply Chain: Harvesting green beans at the peak of ripeness. Speed is critical here; our machines run fast to beat the heat of the day.

6. What Farmers Are Saying

We can talk engineering all day, but the proof is in the hopper. Here is some real feedback.

⭐⭐⭐⭐⭐ Alessandro, Bean Farmer, Veneto, Italy

"We grow the famous 'Fagiolo di Lamon'. It is a protected variety, very expensive. We used to pick by hand because machines ruined the pods. The Ever Power BH400 changed that. It is gentle enough that we still get the premium price, but we finish harvest in 2 days instead of 2 weeks."

⭐⭐⭐⭐ Mike, Kidney Bean Grower, Michigan, USA

"Shipping the container from Italy took a bit longer than I wanted, but the machine is built like a tank. The metal thickness on the chassis is double what my old harvester had. It handles our rocky soil without bending the pickup teeth."

⭐⭐⭐⭐⭐ Ahmed, Broad Bean Producer, Egypt

"We need a machine that can work in very dry, dusty conditions. The air filtration on the engine and the cleaning fans on this unit are excellent. We get very clean beans, which saves us labor on sorting."

7. Frequently Asked Questions

We hear these questions often. Let's save you some time.

How much does a bean harvester cost to ship to the US or Australia?

What happens if a belt breaks during harvest? Can I get parts?

Can this machine harvest beans that are wet or have morning dew?

Is it difficult to calibrate the settings for different bean sizes?

Ready to Upgrade Your Harvest?

Don't leave profit in the field. Get the Italian reliability your farm deserves.

Informacje dodatkowe

| edited | by hyw |

|---|---|

| model | 4BYQ-2.6 |