Agricultural Heavy Duty Bean Harvester for Efficient Crop Harvesting

Ever Power Heavy Duty Bean Harvester: Industrial Italian engineering. Reinforced chassis & high-torque gearbox for massive yields. Factory direct pricing. Get a quote!

We’ve been in the trenches of agricultural machinery for over 18 years now, and if there is one thing we’ve learned, it’s that "heavy duty" is a term that gets thrown around too loosely these days. Real durability isn't just about painting a machine black; it's about steel thickness, weld quality, and torque ratings. If you are in the market for an Agricultural Heavy Duty Bean Harvester that can handle 1,000-acre campaigns without shaking itself to pieces, you’ve come to the right place. As a premier manufacturer and global supplier (we ship straight from our factory in Italy), Ever Power builds machines for farmers who don't have time for downtime. We’ve seen competitors try to cut costs with thinner gauge sheet metal, only to have the chassis crack after two seasons of hard clay soil. We don't play that game.

1. Product Overview: The "Tank" of Bean Harvesting

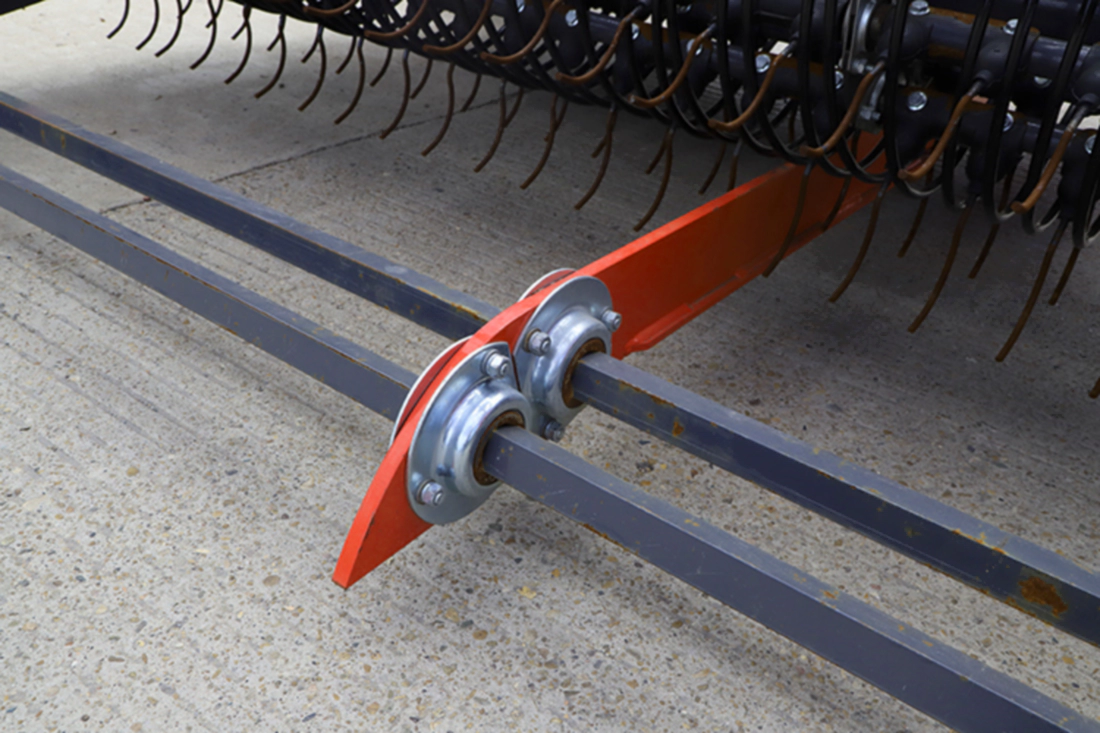

This isn't your average garden-variety picker. The Heavy Duty (HD) series is engineered for extreme conditions—rocky fields, heavy weed pressure, and high-yield biomass. While standard harvesters focus on finesse (which ours still has), the HD series adds brute strength to the mix. It utilizes a reinforced sub-frame and oversized bearings to handle the stress of continuous, high-speed operation.

Suitable "Gases" (and Vegetation Types)

We often get inquiries—probably from auto-translate software—asking about the "suitable gases" for this machine. It always gives the engineering team a laugh! Unless you are harvesting propane (joke!), we know you mean Grasses and Crop Varieties. But this brings up a good point: "Heavy Duty" means it can process denser vegetation ("gases") than lighter models.

This machine is tuned to digest:

- Dense Soybean Crops: When the pods are thick, and the stems are tough (green stem syndrome), standard cutters stall. Our high-torque hydraulic motors push through.

- Large Kidney & Fava Beans: These plants are heavy. The HD series has a stronger lift capacity on the reel to pick up heavy, wet vines without bending the tines.

- Green Beans in Mud: Let’s be honest, harvest conditions are rarely perfect. We’ve designed the cleaning fans to handle higher moisture content, ejecting heavy wet leaves that would clog a standard machine.

- Seed Crops (Weed Heavy): Sometimes the field isn't clean. The HD intake throat is 20% wider to swallow biomass without plugging.

2. Technical Specifications

We believe in raw data. Here is the chassis breakdown. (Please fill in your specific tractor HP and row width requirements so we can match the gearbox ratio.

| Item | Unit | Specification |

| Model Name | / | 4BYH-2.6 Type Art Bean Harvester |

| Suspension Mode | / | Hanging type |

| Picker Type | / | Plunger type |

| Working Width | m | 2.6 |

| Power Supply Range | kW | 66-88 |

| Working Speed Range | km/h | 6~10 |

| External Dimensions | mm | 2333×2870×1182 |

| Power Output Speed | r/min | 540 |

| Wheel Distance | mm | 2600 |

| Production Rate | hm²/h | 1.56-2.6 |

| Operators Required | persons | 1 |

| Machine Weight | kg | 1100 |

3. Why the "Heavy Duty" Series? (6 Critical Advantages)

In our experience, you pay for quality once, or you pay for repairs forever. Here is why the HD series is the smarter investment:

1. Reinforced "I-Beam" Chassis

Most harvesters use a C-channel frame. We use a fully boxed I-beam structure for the main spine. This eliminates frame twisting when you are navigating uneven ditches or turning with a full hopper (which can weigh over 2 tons).

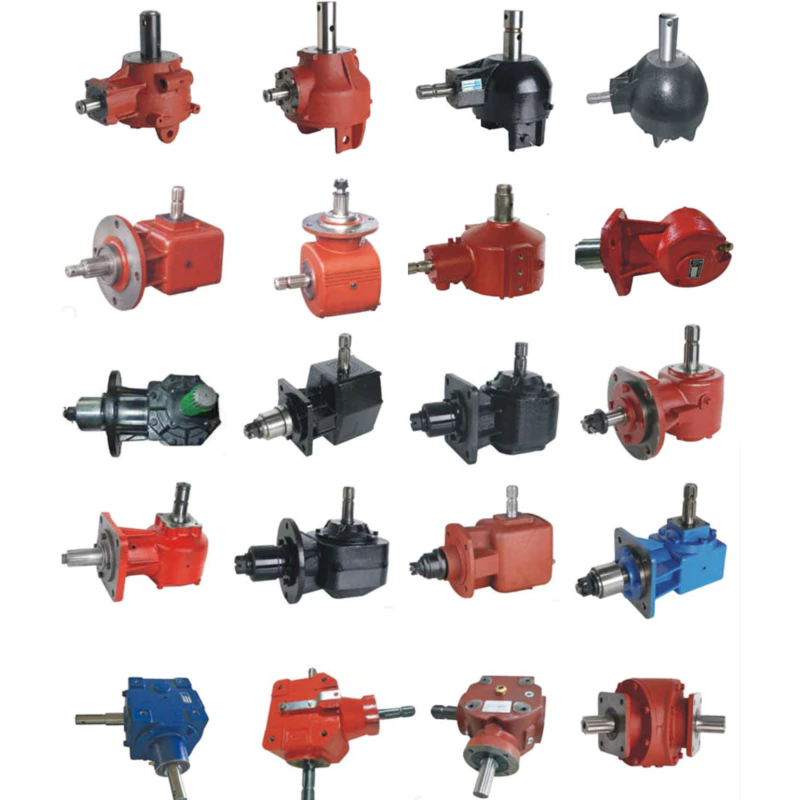

2. The Italian "Titan" Gearbox

We don't use the standard gearbox here. We use the "Titan" series—an oil-bath, cast-iron behemoth made in Bologna. It is rated for 30% more torque than the machine actually needs. Why? So it never breaks.

3. Hardened Picking Fingers

Standard fingers wear out after 300 hours in sandy soil. The HD series uses heat-treated, abrasion-resistant polymer fingers. They cost us more to make, but they last twice as long in the field.

4. High-Volume Hydraulic Cooling

Heat kills hydraulics. We’ve added an oversized oil cooler with a dedicated electric fan on the HD models. This allows you to run 14-hour days in 40°C heat without the system fading or losing power.

5. Stone Protection System

The trick with heavy-duty is to expect the worst. Our concave has a spring-loaded "trap door" that automatically opens if a large rock enters the drum, spitting it out before it smashes the internal bars.

6. "Quick-Change" Wear Parts

We know maintenance happens in the field, not the shop. We designed the HD series with bolt-on wear plates in high-friction areas. You can swap them out in 20 minutes with an impact gun, rather than spending days welding.

4. How to Choose Your Heavy Duty Harvester

If you have a 3-week window to harvest 500 acres, you cannot afford a breakdown. That is who the Heavy Duty harvester is for.

Soil Type Matters: If you farm on abrasive sandy loam or rocky terrain, the HD series is mandatory. The standard machines will sandblast themselves to death internally within a few seasons. The HD's thicker steel resists this abrasion.

Tractor Sizing: Be realistic. The HD harvester is heavier than the standard model. You need a tractor with enough physical weight to control the harvester on hills, not just enough HP to spin the PTO. If you are undersized, the tail will wag the dog.

5. Extreme Applications

This isn't just for the weekend farmer. We see these units in:

- Large-scale Canning Operations: Running 24/7 shifts during peak season.

- Seed Multiplication (Contractors): Operators who move from farm to farm need a machine that can handle the abuse of road travel and varying field conditions.

- Tropical Agriculture: In South America and Africa, where conditions are hot, humid, and rough. The simplified, robust mechanics of the HD series thrive where electronics fail.

We also offer matching gearboxes, PTO shafts, and other related products.

|

|

6. From the Field (Customer Reviews)

We build them tough, but don't take our word for it.

⭐⭐⭐⭐⭐ Antonio, Contract Harvester, Puglia, Italy

"We harvest Borlotti beans in very rocky soil near the coast. My previous machine cracked the axle twice. The Ever Power HD600 is a tank. It is heavy, yes, but it just eats the rocks and keeps going. The stone trap system saved me at least €5,000 in repairs this year."

⭐⭐⭐⭐ Frank, Soy Grower, Iowa, USA

"Buying direct from Italy was a leap of faith, but the price for this amount of steel was unbeatable. It’s simple, mechanical, and built heavy. We put 600 hours on it this season with zero downtime. Just grease and go."

⭐⭐⭐⭐⭐ Diego, Bean Producer, Brazil

"The humidity here kills electronics. I love that this machine is mostly mechanical and hydraulic. The gearbox is massive. It handles the thick, green stems of our second-crop beans better than the big combines."

7. Frequently Asked Questions

These are the questions we get from serious buyers.

How much does shipping a heavy-duty harvester cost?

Does the extra weight of the HD model cause soil compaction?

Can I get parts for the hydraulic system locally?

What is the lifespan of the Heavy Duty gearbox?

Stop Fixing, Start Harvesting.

Get the machine that pays for itself in uptime.

Детали

| edited | by hyw |

|---|---|

| model | 4BYH-2.6 |